Unearthing gold in Toronto

/I just got home from Toronto, the mining capital of the world, after an awesome weekend hacking with Diego Castañeda, a recent PhD grad in astrophysics that is working with us) and Anneya Golob (another astrophysicist and Diego's partner). Given how much I bang on about hackathons, it might surprise you to know that this was the first hackathon I have properly participated in, without having to order tacos or run out for more beer every couple of hours.

PArticipants being briefed by one of the problem sponsors on the first evening.

What on earth is Unearthed?

The event (read about it) was part of a global series of hackathons organized by Unearthed Solutions, a deservedly well-funded non-profit based in Australia that is seeking to disrupt every single thing in the natural resources sector. This was their fourteenth event, but their first in Canada. Remarkably, they got 60 or 70 hackers together for the event, which I know from my experience organizing events takes a substantial amount of work. Avid readers might remember us mentioning them before, especially in a guest post by Jelena Markov and Tom Horrocks in 2014.

A key part of Unearthed's strategy is to engage operating companies in the events. Going far beyond mere sponsorship, Barrick Gold sent several mentors to the event, the Chief Innovation Officer Michelle Ash, as well as two judges, Ed Humphries (head of digital transformation) and Iain Allen (head of digital mining). Barrick provided the chellenge themes, as well as data and vivid descriptions of operational challenges. The company was incredibly candid with the participants, and should be applauded for its support of what must have felt like a pretty wild idea.

Team Auger Effect: Diego and Anneya hacking away on Day 2.

What went down?

It's hard to describe a hackathon to someone who hasn't been to one. It's like trying to describe the Grand Canyon, ice climbing, or a 1985 Viña Tondonia Rioja. It's always fun to see and hear the reactions of the judges and other observers that come for the demos in the last hours of the event: disbelief at what small groups of humans can do in a weekend, for little tangible reward. It flies in the face of everything you think you know about creativity, productivity, motivation, and collaboration. Not to mention intellectual property.

As the fifteen (!) teams made their final 5-minute pitches, it was clear that every single one of them had created something unique and useful. The judges seemed genuinely blown away by the level of accomplishment. It's hard to capture the variety, but I'll have a go with a non-comprehensive list. First, there was a challenge around learning from geoscience data:

- BGC Engineering, one of the few pro teams and First Place winner, produced an impressive set of tools for scraping and analysing public geoscience data. I think it was a suite of desktop tools rather than a web application.

- Mango (winners of the Young Innovators award), Smart Miner (second place overall), Crater Crew, Aureka, and Notifyer and others presented map-based browsers for public mining data, with assistance from varying degrees of machine intelligence.

- Auger Effect (me, Diego, and Anneya) built a three-component system consisting of a browser plugin, an AI pipeline, and a social web app, for gathering, geolocating, and organizing data sources from people as they research.

The other challenge was around predictive maintenance:

- Tyrelyze, recognizing that two people a year are killed by tyre failures, created a concept for laser scanning haul truck tyres during operations. These guys build laser scanners for core, and definitely knew what they were doing.

- Decelerator (winners of the People's Choice award) created a concept for monitoring haul truck driving behaviour, to flag potentially expensive driving habits.

- Snapfix.io looked at inventory management for mine equipment maintenance shops.

- Arcana, Leo & Zhao, and others looked at various other ways of capturing maintenance and performace data from mining equipment, and used various strategies to try to predict

I will try to write some more about the thing we built... and maybe try to get it working again! The event was immensely fun, and I'm so glad we went. We learned a huge amount about mining too, which was eye-opening. Massive thanks to Unearthed and to Barrick on all fronts. We'll be back!

Brad BEchtold of Cisco (left) presenting the Young Innovator award for under-25s to Team Mango.

The winners of the People's Choice Award, Team Decelerate.

The winners of the contest component of the event, BGC Engineering, with Ed Humphries of Barrick (left).

UPDATE View all the results and submissions from the event.

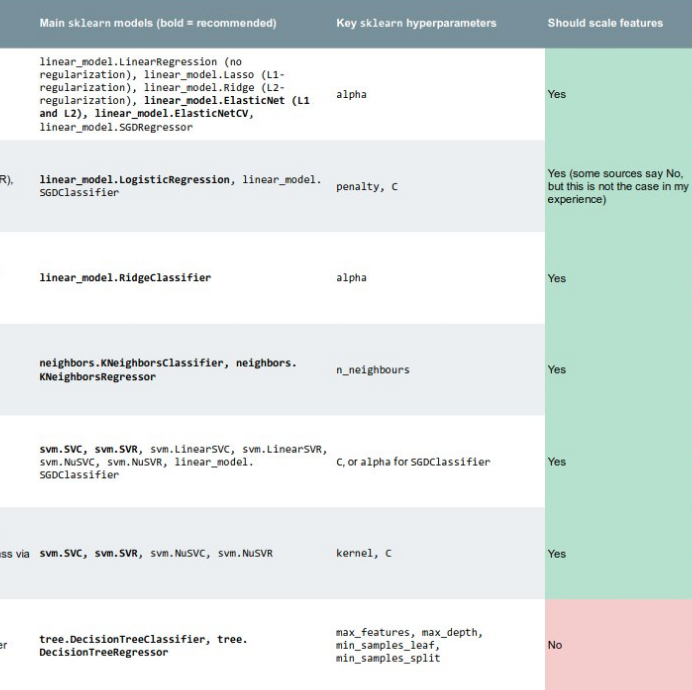

You're in luck! Join us in Paris for the Subsurface Hackathon — sponsored by Dell EMC, Total E&P, NVIDIA, Teradata, and Sandstone. The theme is machine learning, and registration is open. There's even a bootcamp for anyone who'd like to pick up some skills before the hack.

Except where noted, this content is licensed

Except where noted, this content is licensed